As the nation’s leading plastic welding experts, Trinetics Group answers questions all the time about why certain plastics ultrasonically weld better than others. What our experts have discovered through years of training, testing, and consulting is it’s really more about the physical and molecular structure of the plastic as well as the type of welding process that makes the most difference.

All plastics have defined and specific characteristics. Most plastics used within the automotive, aerospace, marine, and consumer product industries are made from different types of resins. The plastic starts out as a liquid which cures over time to form a solid shape. It’s important to understand the fundamental differences between plastics prior to manufacturing your product. Amorphous vs. Semi-crystalline are two types of plastics that should bear full scrutiny and research early on in the product design phase, which will avoid costly pitfalls once you get to the manufacturing process.

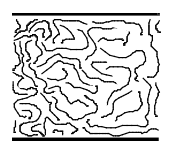

Amorphous plastics by definition means the molecules inside do not have a defined shape or form. As a result, amorphous plastics are harder. At Trinetics Group, we have found that Amorphous plastics are much easier to weld due to its random configuration, because when it is heated, it melts together at the molecular level. Amorphous plastics lend themselves to far-field Welding, which means the horn is greater than a quarter of an inch from where the contact is happening. Some examples of Amorphous plastics are Acrylic or ABS.

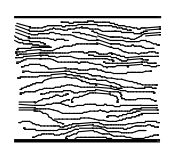

Semi-crystalline plastics, on the other hand, have a highly ordered molecular structure with a sharp melting point. Semi-crystalline plastics do not gradually soften with a temperature increase. Semi-crystalline plastics remain solid until a specific quantity of force or heat is absorbed and then it rapidly changes into a viscosity liquid. Semi-crystalline plastics almost always require near-field welding, which means the horn is less than a quarter of an inch from where the contact is happening. Some examples of Semi-crystalline plastics are Polypropylene and Polyethylene.

When it comes to ultrasonic welding, Trinetics Group uses industry-leading equipment made by Dukane. The welder uses a horn on a stack and the ultrasonic vibrations cause friction between the parts and the heat welds the two parts together at the molecular level. Both Amorphous and Semi-crystalline plastics have different melting points. Since their molecular structures are different, the effort it takes to achieve optimum results for either plastic is also different. Let us explain why.

The randomized molecular level of Amorphous plastic works well when ultrasonic welding is applied, because as the horn increases the amount of movement of the molecules, it bounces the sound waves around a lot, making it much easier to weld. The amount of pressure needed to be applied to the horn on the Amorphous plastic is lower to get it hot enough to melt it and make it join more quickly than Semi-Crystalline. The Amorphous plastic molecules absorb the heat rather than transferring it.

Semi-crystalline plastics have molecules that are more uniform. When using ultrasonics to weld Semi-crystalline plastics, the vibration sound waves resonate more uniformly across the plastic which require increased wattage that produces more energy to weld. By increasing the pressure, the Semi-Crystalline plastics can be welded effectively. However, in the process Semicrystalline plastics are likely to flex and bend, becoming softer. Semi-crystalline plastics are unlikely to break because of this stretching.

One common problem found in using Semi-crystalline plastics is not having enough power or amplitude to create a weld and this sometimes results in melting the top of the part’s surface. When more pressure is applied, the part may absorb too much energy and with the generator spiking its wattage, it begins to burn or defect at the contact surface between the horn and the part. The solution to this problem is increasing the amplitude by moving up a booster or possibly by going to a lower frequency. Semi-crystalline plastics often need a higher wattage generator and a booster of at least 2.0, increasing the amplitude out of the generator by a factor of two, to achieve optimum performance.

If problems still occur, then it may be time to switch the plastic or the welding process. If Ultrasonic Welding is not producing the desired results, then consider using infrared or spin welding to achieve the same effect. If your joining process requires plastic welding, and if you are using Semi-crystalline plastics, you may have to switch to Amorphous plastic to achieve the desired results.

If you or your colleagues have questions about which plastic Amorphous or Semi-crystalline to use, don’t hesitate to contact Trinetics Group at 321-622-8584 or email us at info@trineticsgroup.com for more information.